Before I’d figured out the name for what you now know as Hands®, I knew that whatever it was going to eventually be called had to be human. I felt that there would be no sense whatsoever in it existing as a bike club, if I didn’t acknowledge that it was hand-built by some imperfect and flawed human beings. With that in mind, it’s so validating to see this sentiment being celebrated. For all the threat of automation Taking Our Jobs® (and the ensuing Artisanal trend for handmade tat products in response), there still exists a small pocket of the industry that has carried on just as it always has done for over a hundred years. In amongst all the BS, this slice of heaven harks back to a simpler time, when things worked. A time where we took time, and pride, in making things. There’s a two-letter acronym that is never going to be mentioned on this website that I’m sure you’ve all heard enough of over the last three years. You won’t find any hints of its existence anywhere on this website, neither will you find any trace of it at a small Victorian factory in Smethwick, just on the outskirts of Birmingham.

When words like ‘handmade’ or ‘made in {insert locale here}’ are used, it usually prompts me to generate an image in my head of a little person with a hammer, stood in a saw-tooth roofed factory, making something out of wood, metal or leather. At least, that’s what the teenage-brain that I observe the world from, thinks. It’s like the haute couture horror stories we hear about Hi–Fashion™ brands putting laces in shoes on Italian soil, but the shoes were actually made in factories on the other side of the planet – just to be labeled ‘Made in Italy’. We all know that a lot of the time, ‘Handmade’ don’t mean jack. It’s a marketing-led, box-ticking exercise, designed to out-do a competitor, and hopefully add some more zeroes to the price tag. Handmade, organic, artisanal, specialist, Pro Max. You get the idea.

It’s not just specific to Italy and high fashion of course. You might not have the same generative settings that I do, but imagine it like this: a lot of (not all) people think the UK is full of people in bowler hats and bonnets, drinking tea, riding on red buses and black cabs. We all immediately get annoyed because we know the UK isn’t like that at all. But, what if I told you that there’s a little bit of the UK that might not be bowler hat-wearing tea drinkers, but is made up of saw-tooth roofed factories with hammer-wielding workers making saddles out of wood, metal and leather.

For years, I’d always wanted a Brooks saddle (on my fixed lol) and so did my dad (on his MTB). I didn’t know why, but like adidas predators on Becks, like Paddington’s marmalade and Wallace’s cheese, it had to be a Brooks. There was just something about the saddles compared to the plastic ones my BMX had that didn’t feel ‘whole’. Fast forward a decade and we now have multiple Brooks saddles on all of our bikes. So does my gf and pretty much all of the Resident Ryderz® at Hands®. It’s only now that I’ve put some serious mileage with my backside on one, that I now understand that it wasn’t just hype, it was real.

A couple months back, the internet was graced with this video from Blue Lug. At the time, I had no idea that it was in anticipation of a collaboration between Brooks and Blue Lug. I’d just assumed that they were granted inside access, being the brilliant and respected shop they are. Being a bunch of nerds who share a love for all things genuinely handmade, Hands® has a combined view count for about half of the video’s current views. After rewinding, replaying and Zooming In© we all separately checked to see if there was a way that we could see inside the factory, unfortunately, to no luck.

Then, as if they’d seen our search engine history, they opened the doors. Somehow, it was also the first time in over 160 years that they’d opened them to the public, with no record of it ever happening before. The group chat was in a shambles – book now, book now, book now. We locked in the four most eager Saddle Sniffers™: myself, Jan, Jamie and my Old Man®.

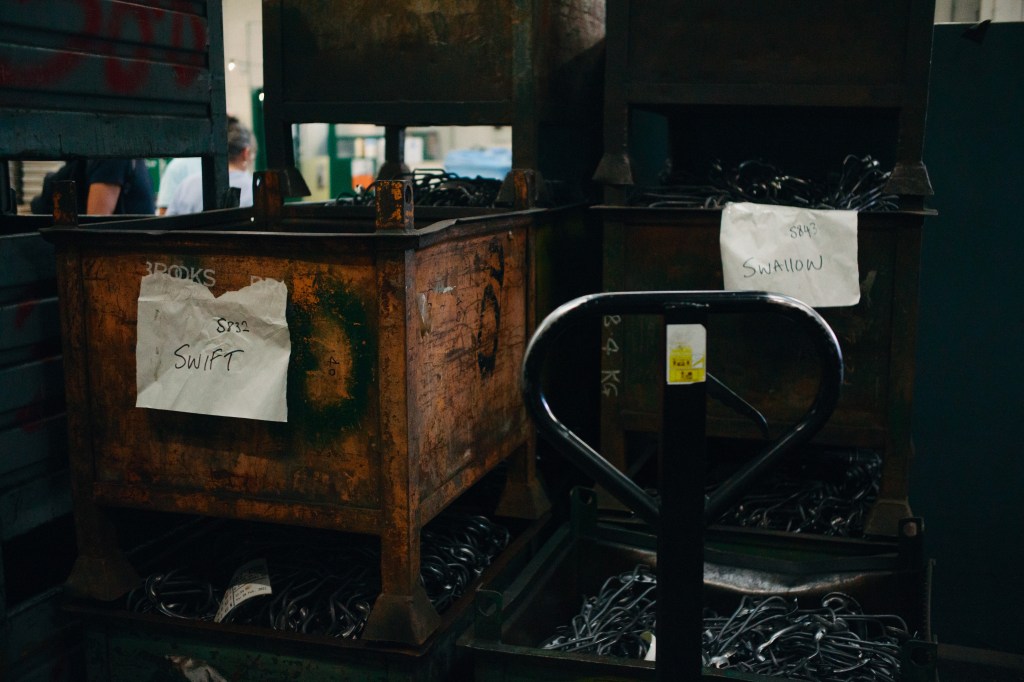

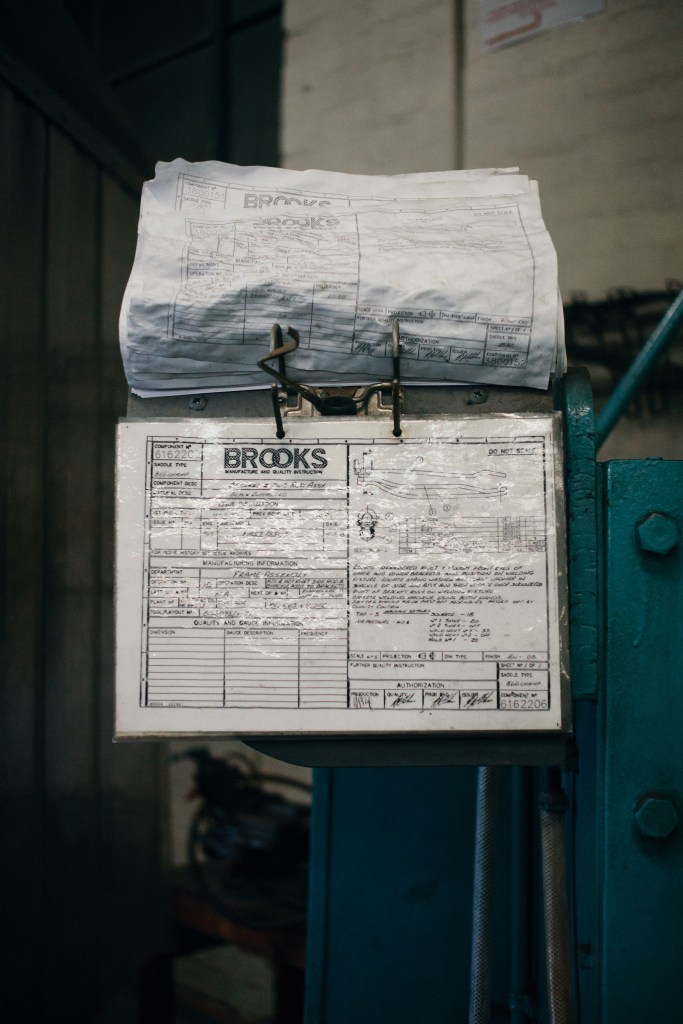

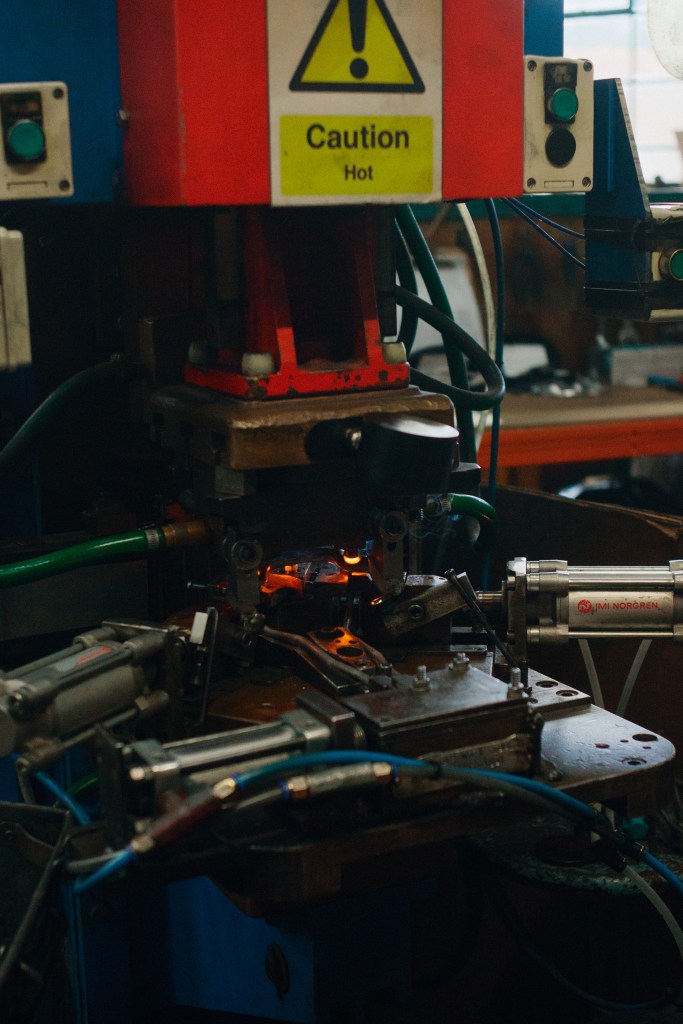

To say we had a brilliant time would be a total understatement. That factory is special. What they manage to do there, on that scale, to that level of quality and for the amount of time they’ve been doing it for is testament to this country’s history of industry and manufacturing (that’s now mostly gone). Hand-built machines making handmade products designed to last a lifetime. The reuse and recycling of materials, keeping wastage down by sharing unused and discarded resources with the local industrial community. Literally: bits of metal that can’t be used by Brooks get sent to other factories and smelted down to be remade into nuts and bolts. Just like the saddles, every level of detail in the production process has been meticulously thought through and refined, not in the name of efficiency or streamlining, but just to make the process better as a whole. No automation on this factory floor.

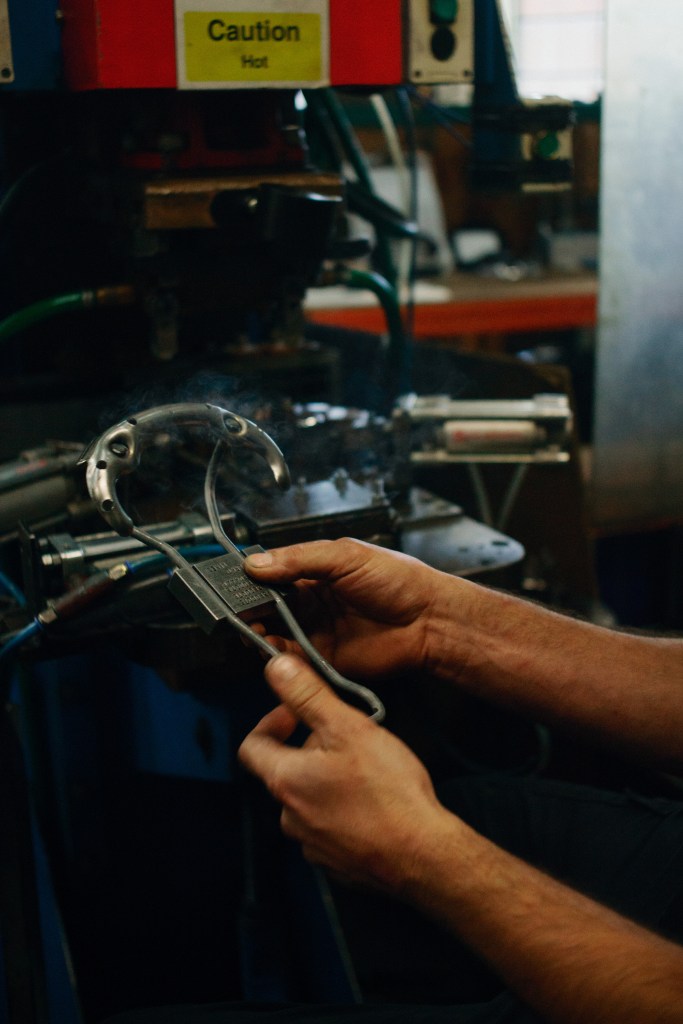

We immediately gravitated towards the workers, nerd-mode® engaged. We learned that there is only ever 16 people max working on the floor at a given time, and on a good day, roughly 1000 saddles are made. We kept on falling behind from the main tour group, lost in the nerdiness. Łukasz showed us how some of the machinery actually works: steaming, freshly-welded rails for B17s that were still hot to touch (H&S no-no, sorry Stefan lol), and the comparison of brittle-ness between the steel and titanium struts (Jan even got to snap one).

20-year strong Steve showed us how filing down a discarded, broken rail helps to slip a bolt onto the inside of the springs on a B67. And even though it looks hard to use your hand to press the mounting bolts onto the hammock-y bit of the saddle, ‘you do get used to it after a couple years’.

Magda let us get up close and personal with the pre-moulded leather, showing us the moulding process and the parts required. Producing the shapes that our nether-regions all know and love involves a ridiculous amount of psi pressing into CNC’d chunks of metal – some over 60 years old.

Zsolt, armed with a sharp implement and forearms like Popeye, taught us how all it takes is one swift movement to trim the excess leather from the saddle edge. A technique perfected from over a decade of experience that made it look as easy as slicing through warm butter – just for us to give it one go and make a proper Pigs Ear of it.

John and Deepak, who we were all excited to meet after watching the Blue Lug tour, so we could witness IRL the precision with which they strike a hammer or chamfer edges of a saddle. They had no idea that this was the most viewed part of the video tour – to them, they were just doing their job. We asked them if they rode, to which they rebuffed: ‘Are you mad? Have you seen the roads outside?!’

Finally, Steve (I actually had to apologise before we left due to how far behind his tour we were), who comes from a generation of saddle makers for Brooks. His dad built machines that still run today, and he’s probably made many of the saddles we spend so much time on. When you hear someone speak about the role with the enthusiasm he did – no stone left unturned in the detail – it goes beyond being just a ‘brand’ that makes nice saddles.

It’s not often that you get to see behind the veil, especially for something that you really love and respect. Increasingly, a lot brands have started putting on tours and experiences, to show you how they ‘get stuff done’. But it can feel forced, staged and even fabricated too, just to fit a marketing narrative. But like any good product that is built to last, you can tell by the patina when something is real. This factory, and the people who run it, are real. They love what they make, they’re proud of it, and I’m sure – if things don’t change too drastically, they’ll keep on doing what they have been doing since 1866 for many years to come.

Big love to Stefan, Riccardo, Steve and everyone else whose name I’ve forgotten. Cheers!

Leave a comment